Stretch Film Quality Classes: The Key to Optimizing Packaging Efficiency and Cost Savings

1. Technical Analysis of Stretch Film: From Basics to Advanced Solutions

Stretch film, primarily made from linear low-density polyethylene (LLDPE), achieves differentiated performance through multi-layer co-extrusion technology. Core technical parameters include:

Elongation: Quantitative measure of stretch capacity (150%-370%)

Puncture Resistance: Ability to withstand sharp impacts (≥300g/μm)

Cling Force: Adhesion between film layers and cargo surfaces (0.8-1.5N/cm²)

Memory Retention: Ability to maintain consistent tension after wrapping

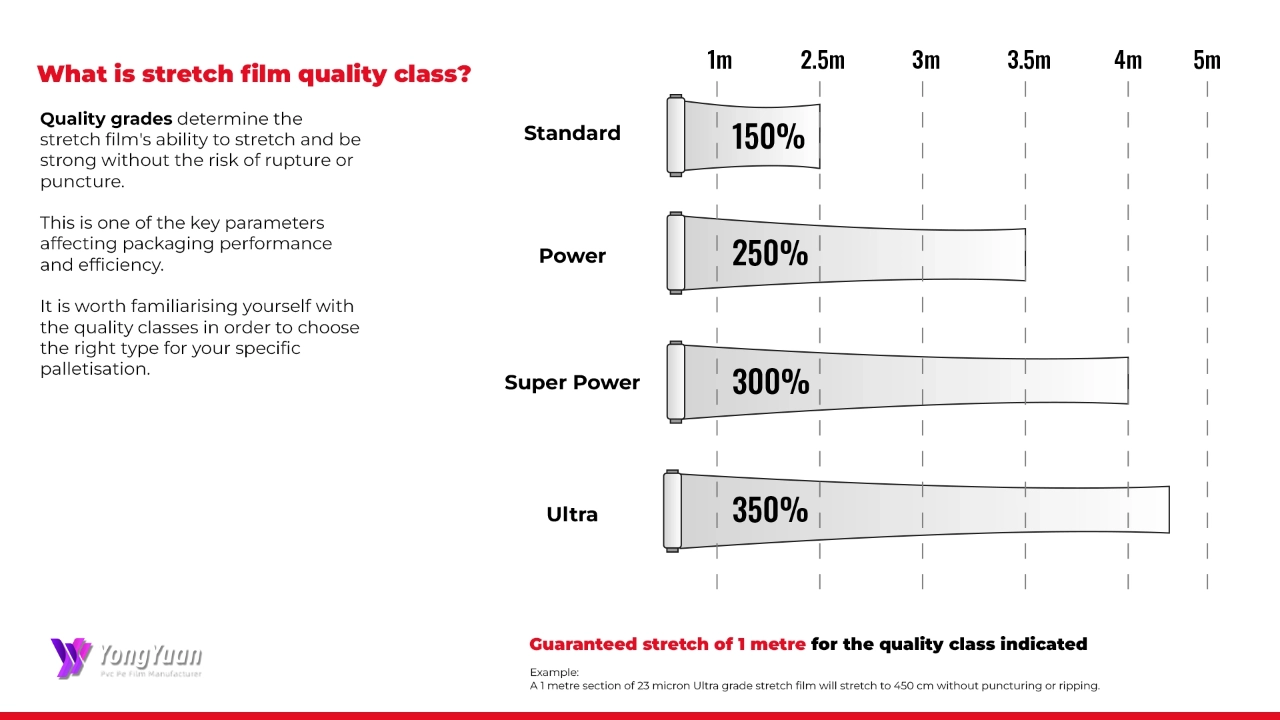

2. Quality Classification System: Four Tiers for Precision Application

Tier 1: Standard Grade

Performance: 150%-200% elongation, 17-25μm thickness

Applications: Manual wrapping of lightweight cartons and regularly shaped goods

Innovation: "Standard+" variants with nano-reinforced tear resistance (20% improvement)

Tier 2: Power Grade

Breakthroughs: 250%+ elongation, 300% pre-stretch ratio

Tech Highlights: Triple-layer co-extrusion (core/cling/abrasion-resistant layers), thickness reduced to 12μm

Cost Efficiency: 40% larger coverage per roll vs. Standard Grade, ideal for automated lines in food and FMCG industries

Tier 3: Super Power Grade

Elite Performance: 300%+ elongation, -50°C low-temperature resistance

Advanced Uses:

Rust-Proof Packaging: Integrated VCI (vapor corrosion inhibitor) layers for automotive parts

Cold Chain Logistics: Anti-condensation additives to block moisture ingress

Certifications: Complies with ISTA 3E, ASTM D4649 international transit standards

Tier 4: Ultra Grade

Technological Peak: Five-layer nano-co-extrusion, 370% elongation, 9μm thickness

Smart Features:

Tension-Sensing Color Markers: Visual indicators of wrap tightness

UV-Detection Layer: Color change signals film degradation

Key Users: Aerospace component manufacturers, precision instrument suppliers

3. selection Framework: A Four-Dimensional Evaluation Model

Cargo Profile

Weight Class:

Grade Load Capacity Standard ≤500kg Power 500-1,500kg Super Power 1.5-3 tons Ultra ≥3 tons Shape Complexity: High-cling films for irregular items

Equipment Compatibility

Manual Wrappers: Match 200%-250% elongation

Auto Pre-Stretch Machines: Require 300%+ elongation and precise tension control

Environmental Demands

High-Temperature Warehousing: Cross-linked films (80°C+ resistance)

Cross-Border Shipping: UV-blocking and anti-static coatings

Cost Equation

Cost per Pallet = (Film Price × Consumption) + Labor/Depreciation

Industry data shows Power Grade films reduce total costs by 18%-25%.

4. Industry Trends: Sustainability Meets Smart Innovation

Eco-Friendly Evolution

Bio-Based PE Films: Made from sugarcane ethanol, 2-year degradation cycle

Water-Soluble Films: Dissolve in 1 hour, certified by Amazon and Alibaba

IoT Integration

Embedded RFID Chips: Monitor packaging integrity in real time

Tension Analytics: AI algorithms optimize film usage and reduce waste

Custom Solutions

Branded Colors: Custom hues for enhanced brand visibility

Multi-Functional Films: Combine anti-counterfeit tags and temperature-sensitive indicators

5. Quality Assurance: Three-Step Verification Protocol

Lab Testing: Validate elongation strength and oxygen permeability via SGS reports

Field Trials:

drop Test: 1.2m free-fall x3 without film rupture

Vibration Test: ISTA-compliant 2-hour shaking with zero tension loss

Cost Audit: Compare material consumption per unit volume

Conclusion

With packaging costs accounting for 12% of total logistics expenses (per DHL research), strategic selection of stretch film grades is a critical lever for supply chain optimization. By aligning technical specifications with operational needs, businesses enhance cargo safety while building cost resilience in a volatile market. Partner with certified suppliers for tailored solutions—every roll of film can become a catalyst for profitability.